Resin

Casa 01

Poliuretano

Poliuterani 2

Our job is carried out in the following stages:

- Cut of foam polyuretane blocks, of different qualities and thickness, to obtain slabs, pillows, mattresses, sponges, filters, stuffings...

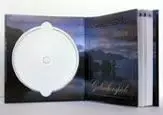

Matching of sheet of cardboard with resin and paper, in order to obtain a padded support suitable to different ends; first of those is to get quadrants for notebook and related products (Bookbinders and Stationery).

The process of gluing is done with vinyl glue or with hot adhesive, total or partial stick, positioned where the cut of the quadrant will go.

The following materials are used:

- Cardboard of different thickness( usually from 0.5 to 4 mm) made by Kappa boards

- Resin of different thickness (usually from 2 to 4 mm) different density, according to specific solutions

- Paper of 120 gr/m2 and patinated (very stable) from 240 gr/m2 that give a high quality product.

Cutting machinery in any size, of matched foils or only cardboard, with circular knives, linear and with hollow punches (die-cutting also of boards with round corners).

Production of foam boards ("SANDWICH") with turned-up flaps (turn-up on both-shorter or longer-side).